Pumps are the driving force behind the movement and distribution of water, making sure it reaches where it’s needed the most—whether for drinking, agriculture, industry, or sanitation.

Different types of pumps are designed to cater to specific applications, ensuring efficiency and reliability in water management.

For a pump to operate properly, it must be free from air and filled with liquid. This brings us to the concept of pump priming.

What Is Pump Priming?

Pump priming refers to a process of preparing a pump to operate effectively by removing air from its casing and suction line.

This priming process involves filling the pump’s casing and impeller with fluid before starting the pumps. The pump casing (the outer shell that seals the interior, maintains the pump’s pressure, and prevents air from being introduced) must be filled with liquid.

If the casing contains trapped air, vapours, or gases, it can disrupt the pumping process and cause severe damage.

Priming also eliminates the risk of cavitation (air bubbles caused by pressure variation) and prevents damage to the metal components.

Centrifugal and positive displacement pumps need priming in the initial startup phase. While self-priming pumps do not require manual priming, these pumps automatically do the priming process in the initial phase.

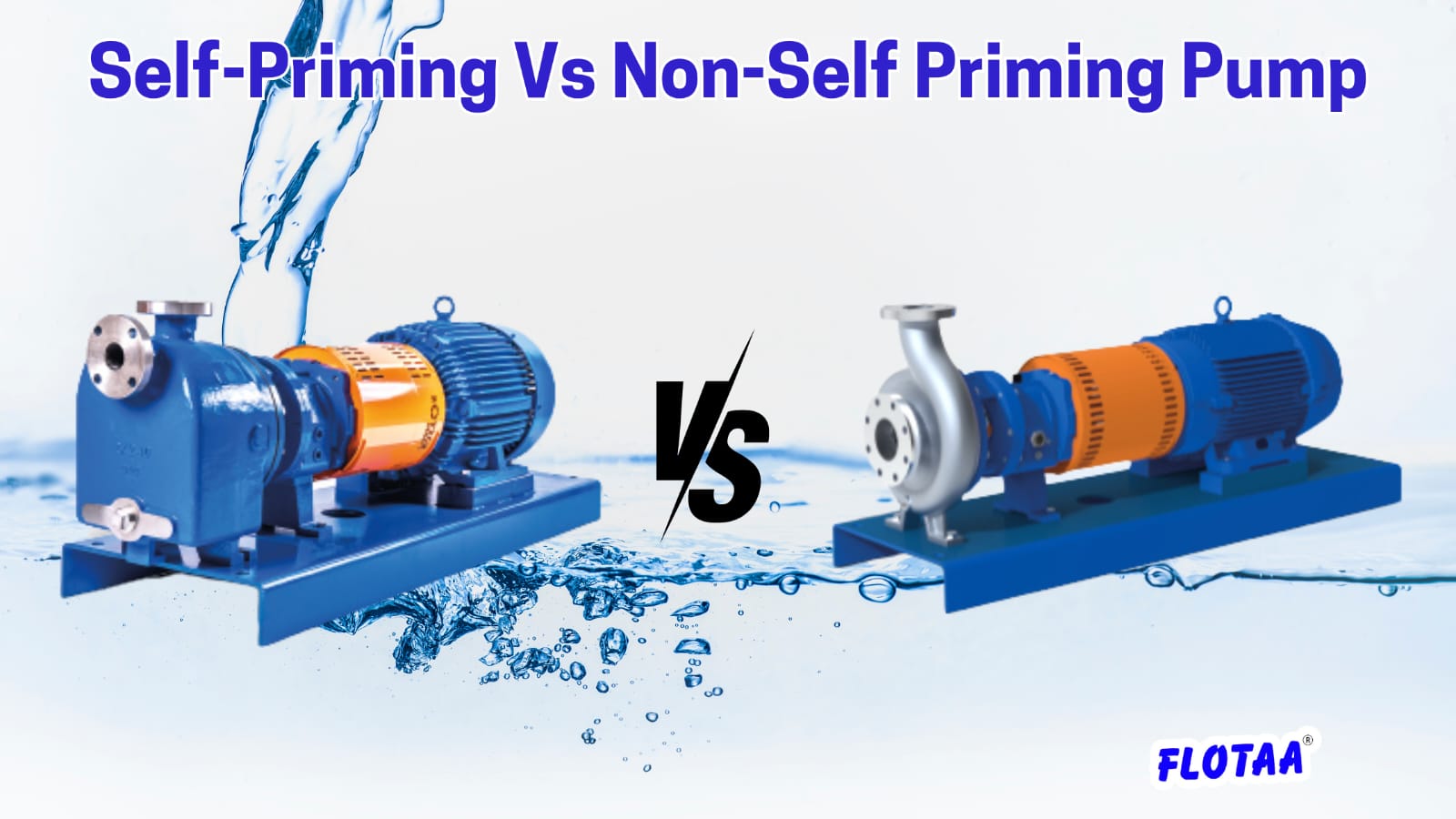

On the priming base, pumps are classified into two parts.

- Self-priming pumps

- Non-self-priming pumps

Let’s understand self-priming and non-self-priming pumps, their working procedures, applications, pros and cons, and their differences in detail.

What Are Self-Priming Water Pumps?

Self-priming is a type of centrifugal pump that automatically removes air or gases during the priming process. They create a vacuum by releasing air through the suction point until the fluid is completely filled between the casing and the impeller.

Working Procedure Of Self-Priming Water Pumps

1)- The pump casing is initially filled with liquid, which might come from a priming reservoir or a recirculation system.

2)- When the impeller rotates, a centrifugal force removes the initially present liquid and air through the suction point. This process develops a vacuum in the pump.

3)- This vacuum helps pull fluid into the casing. The fluids filled the space of the released air in the casing.

Self-priming pumps contain check and flapper valves, which prevent fluid from flowing back and air from being introduced into the pump during the pumping cycle.

When the priming process is completed, fluid flows continuously through the pump. These pumps always release a small amount of air from the casing to work efficiently.

Applications Of Self-Priming Water Pumps

- Self-priming pumps are used to lift and transfer liquids in industrial, municipal, and sewage treatment plants.

- It can handle sediments and debris on construction sites and pump them for dewatering.

- They help marine ships and other vessels remove the water with garbage.

- It removes different fluids in various industries, such as chemical transfer, food and beverage processing, and pharmaceutical production.

- It is also used in irrigation and agriculture to pump water from various sources.

Self-priming pumps help remove large volumes of water during flood control and emergencies, such as waterlogging caused by heavy rain.

Pros And Cons Of Self-Priming Water Pumps

Pros

- Self-priming pumps are less expensive than other pumping machines.

- The main component is above the water surface, so maintenance is easy.

- It can handle solids up to 3 inches.

- The self-priming, no need to merge into liquid for pumping like other pumps (submersible)

Cons

- Manual priming is needed before their first use.

- It frequently needs higher clearance to handle solids.

- It needs a large volume for self-priming.

- A minimum pipe length is needed to minimise air leakage and suction pressure loss during distance source pumping.

- When the water level is high, the motor needs protection.

What Are Non-Self-Priming Water Pumps?

The non-self-priming pumps require manual priming to evacuate the air initially. The air or gas can be removed manually or using an external device. It works properly when the air is completely removed from the casing.

Working Procedure Of Non-Self-Priming Water Pumps

1)- Non-self-priming pumps require manual operation to fill the fluid in the casing. They cannot evacuate air or introduce liquid automatically.

2)- Before starting the pump, ensure the fluid is appropriately filled in the casing and the air is released. The pump can be started when manual or external devices complete the priming process.

3)- A foot valve prevents the air from entering the pumps, and the centrifugal force helps move the pump’s water through the inlet suction point. One or two impellers separate the liquid and discharge it from the pump.

Applications Of Non-Self-Priming Water Pumps

Non-self-priming pumps work for steady liquid flow requirements.

- Used in water treatment plants, they move water with a centrifugal force.

- In chemical processing, to transfer chemicals, corrosive fluids, and other hazardous materials.

Pros And Cons Of Non-Self-Priming Water Pumps

Pros

- Non-self-priming pumps are more efficient than self-priming pumps.

- Due to the simple design, less maintenance is required.

- Cost-effective pumps with lower pricing.

Cons

- The first drawback is the manual priming of the pump.

- They have limited adaptability and may not be well-suited for applications.

- The cavitation due to improper priming can damage the pump components and increase the cost of maintenance.

Difference Between Self-Priming And Non-Self-Priming Water Pumps

| Self-priming water pumps | Non-self-priming water pumps | |

| Requirements and applications | It involves water processing and purification in various fields like the chemical, petrochemical, and pharmaceutical industries. | It involves water processing and purification in various fields like the chemical, petrochemical, and pharmaceutical industries |

| Cost-efficiency | Comparable cost | Lower cost than self-priming pumps |

| Maintenance | Not easy to maintain | Easy to maintain due to simple design |

| Energy Consumption | Efficient energy consumption for air handling process | Energy efficiency varies depending on the design. |

| Processes | Automatic priming | Need manual priming |

Conclusion

Choosing a self-priming or non-self-priming pump depends on how and where you plan to use it.

Self-priming pumps are versatile and work well with various liquid types, including mixtures of debris and water. However, non-self-priming pumps are better for cleaner, less dense environments where continuous operation is needed.

To ensure optimal performance, factors such as pump flow rate, fluid lifting height, and application requirements must be taken into consideration. These factors help you choose the best water pumps that maximise efficiency and minimise maintenance costs.

For the best results, consulting an expert can help match the pump type to your exact requirements, ensuring long-term reliability and performance.

Read More: Types Of Irrigation Water Pumps

0 Comments